Your agitator is our issue

Steverding Agitator Technology manufactures technically matured and sophisticated agitators. Accordingly, the areas of research and development and construction are of great significance. The scientific work is extremely practice orientated, building the basis for Steverding Agitator Technology together with its customers to be on top when it comes to new and even more effective solutions.

Technical Advice

We ideally start with the analysis of requirements and demands. The concept follows a practice-orientated plan keeping a permanent dialogue between the customer and experts. Due to the fact that most of the components required for our agitators are designed and manufactured in-house, we can implement custom solutions within a short period of time.

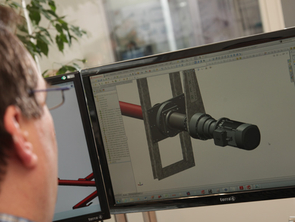

Planning

One facility does not match the other. Different types and dimensions of agitators are required depending on design and size of the facility. Steverding Agitator Technology manufactures agitators in small series as well as custom-made products. With the help of 3D software we at Steverding analyse and design the best agitator for the project. This way we can ecologically satisfy our customer-specific requirements and demands.

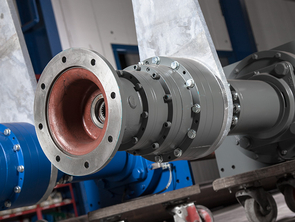

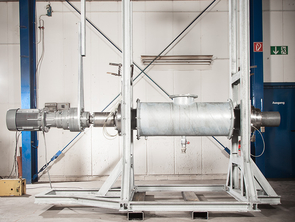

Manufacturing

Steverding Agitator Technology works with the most modern CNC-Technology when manufacturing its agitators. However, the man behind the machine is no less significant. Certification of our experienced and motivated team in areas such as welding is as equally important as a strong collaboration with universities and technical colleges. Nothing is left to chance. The production data is delivered directly from 3D software planning. Agitators with a length of 33 m and a diameter of 6 m pose no problem for us.

Installation

Nobody knows our agitators better than we do. No-one can install our agitators better than we can. On-site installation lies between planning and commissioning. Steverding Agitator Technology relies on its own installation teams. Our highly trained and skilled installers have everything in grip and come to you on-site with our fully equipped service vehicle. – The best and only way to ensure a professional installation and commissioning within the set deadline. Our experienced technicians guarantee this. Our installation teams are out and about for our customers in Germany, Europa and World-Wide. We also offer training courses for installers from other companies at our training centre in Germany.

Service

Being the manufacturer, Steverding Agitator Technology has access to all facility components. Once commissioning of the facility has been completed we remain your contact partner for all wear and tear and replacement parts 24 hours a day, all year round. Biogas facilities run day and night ideally without any interruptions. Strong climate influences, differing flow of goods and mechanical factors could cause dysfunction. We offer service and maintenance and, in the case of a disfunction, repair works carried out by our own qualified service team.

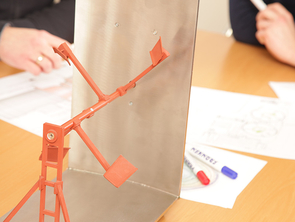

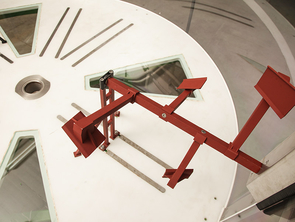

Laboratory / Agitating Tests

Ideally, there should be very little tolerance between theory and practice. Agitating tests under real conditions validate the technical design of our original products.

Basic Research

Compared to modern systems the first agitators for Biogas facilities functioned in an old-fashioned way. EDV supported basic research in combination with scientific institutes, colleges and universities has revolutionized agitator technology resulting in significant progress in the technical design of agitators today. Steverding Agitator Technology works very closely with the Technical College of Steinfurt, Muenster University (Germany) and the Technical University of Vienna (Austria).

ATEX

Steverding Agitator Technology manufactures certified agitators in accordance with the strict guide lines of ATEX Directive 94/9 EG for explosion-hazard environments.

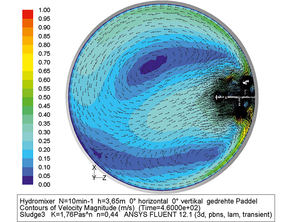

CDF-Simulation

In vertical facilities the flow behaviour is completely different to conventional fermenters. Convincing simulation of flow behaviour has become essential and indispensable for many new applications. With CDF simulation it is possible to obtain important information regarding Newtonian and non-Newtonian flow behaviour. Together with specialists within this sector we can present conclusive scientific analyses.